Technical description of Plastic injection molding machine

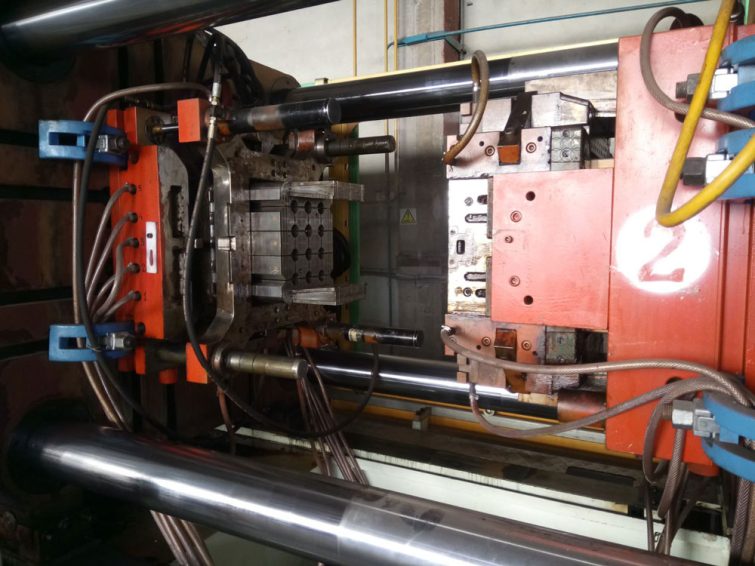

Model of the machine: BT 780 V-I (screw Ø 100)

Manufacturer: Guangzhou Borch Machinery Co., LTD (China)

Content:

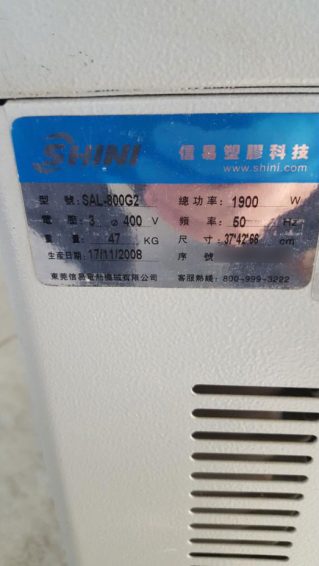

1. Automatic loader SAL 800G 2, 2 h.p.

2. Drying machine with storage bunker SHD 150 + MST: 300

3. Mixer SHINI SVM 150

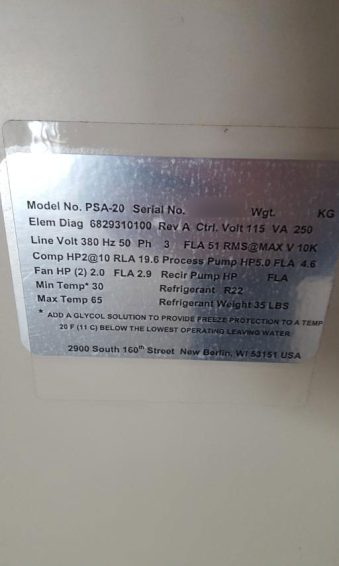

4. Chiller AEC Cooling capacity 72 kWt

5. Crate box mold

Production date: 2008

Period of exploitation: 8500 hours

Closing unit:

- fast-moving slide plate starts movement powered by closure cylinder

- fast-moving slide plate closes itself under high pressure when it approaches to the crate box mold

- there occurs the process of injection and cooling

- the crate box mold opens slowly

- the crate box mold opens fast to the required position

Injection and closing during runtime are made in turn. All actions are provided by hydraulic system under computer control.

Machine parameters

Technical specification

Plastic injection molding machine: BT 780 V-I

Screw diameter : 90/100/105 mm

Max. injection pressure : 180/146/132 MPa

Theoretical injection volume: 3181/3927/4329 cm^3

Shot (injection) weight: 2987/3687/4065 gram

Length-to-diameter ratio: 24:1/22:1/20:1

Crate box mold thickness: 380-975 mm

Opening stroke: 1025 mm

Closing force: 780 tons

Number of heating zones: 7

Space between columns (H x W): 970х970 mm

Pressure plates size (H x W): 1430х1430 mm

Injection stroke :300 mm

Heatings power : 40,6 kW

Hydraulic motor: 37+37 kW

Hydraulic pressure: 17,5 MPa

Oil reservoir volume: 1700 liter

Machine weight: 45 tons

Machine dimensions (L x W x H): 10,5 x 2,43 x 2,5 (m x m x m)

Crate box mold

Dimensions of the molds in the kit (TPA VT 780 V-4): 800 x 700 x 715 mm (height)

Weight: 3 500 kg

Product dimensions (crate for 20 NRW bottles 0,5l): 300 x 400 x 285 mm (height)

Weight: 2,14 kg

Reference: PRO3748