SPECIFICATIONS

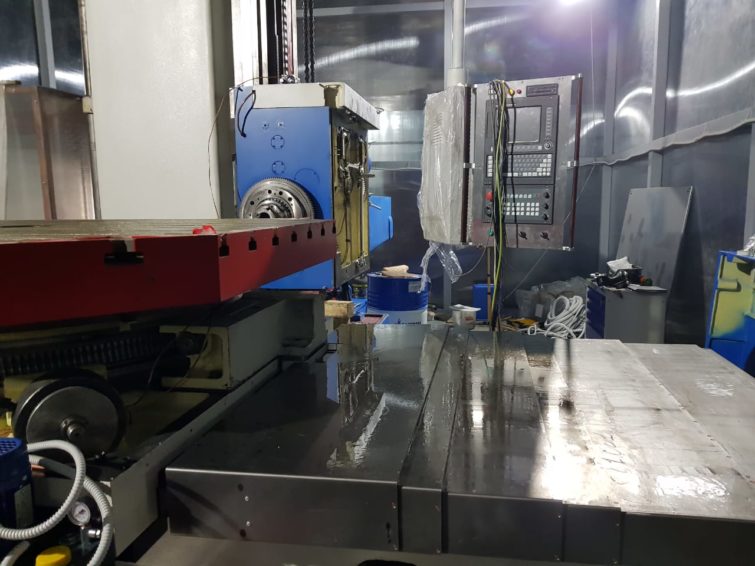

horizontal boring machine 2Н636ГФ-4-УЧПУ-2018 (faceplate) with the device

Numerical Control NC-310 Balt-System

Machine horizontal boring model 2N636GF-4-UCHPU-2018 is designed to perform the following process operations:

– milling of planes, grooves, benches, including contour and volumetric milling;

– drilling, reaming, centering and sinking holes;

– boring and reaming;

– threading holes in holes with taps and cutters;

– turning surfaces, processing annular grooves and trimming the ends with faceplate.

NC control system NC-310 BALT-SYSTEM

Number of controlled coordinates 7 (X, Y, Z, W, B, U, C)

Number of simultaneously controlled coordinates 4 (X, Y, W, B)

Accuracy of positioning linear coordinates on the length of movement 1000 mm ± 0.01 mm

Accuracy class – “P” (4-6 microns) according to GOST 8-82

before the upgrade was “H” (10 microns)

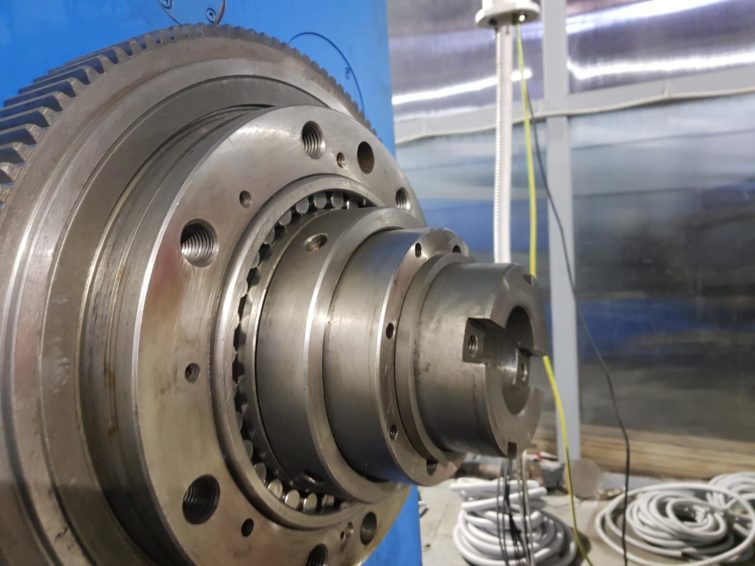

Diameter of normal sliding spindle, mm 125

Diameter of the strengthened sliding spindle, mm –

Cone for fastening tools:

in morse spindle 6

by special order in accordance with GOST 15945-70 50 (7:24)

the largest mass of the processed product, t 8

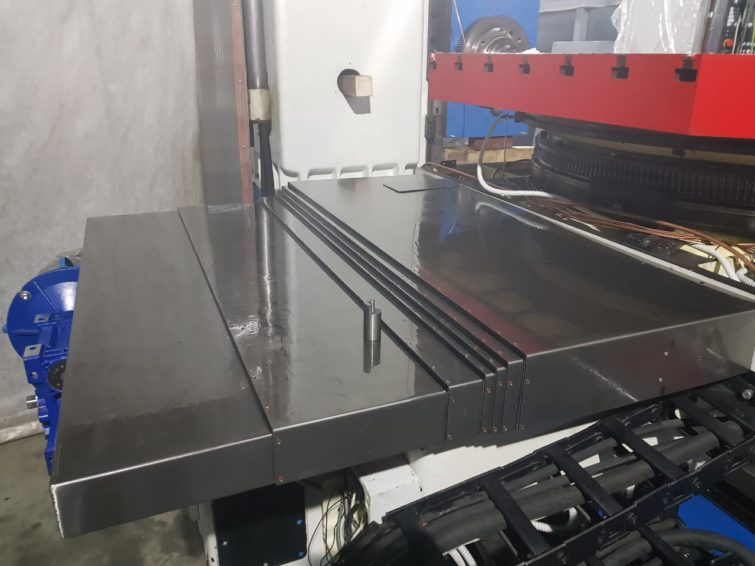

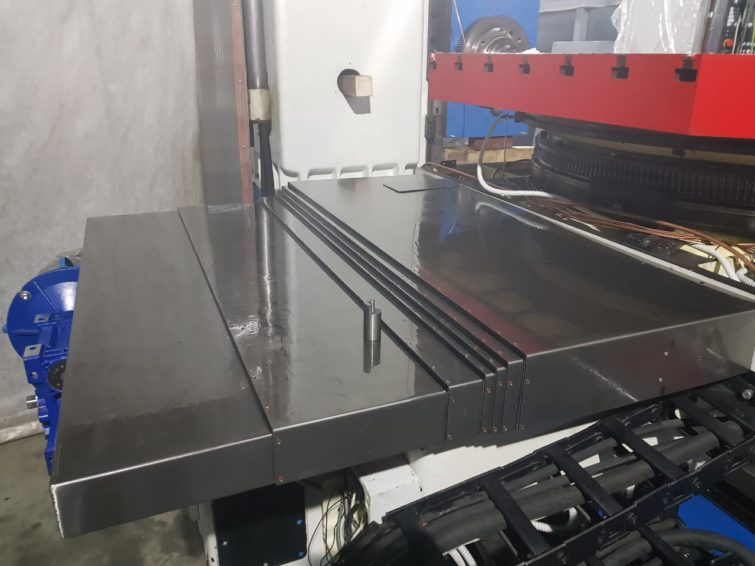

Sizes of the built-in longitudinally movable rotary table in accordance with GOST 6569-75:

width, mm 1600

length mm 1800

number of slots 9

groove width, mm 28

distance between grooves, mm 160

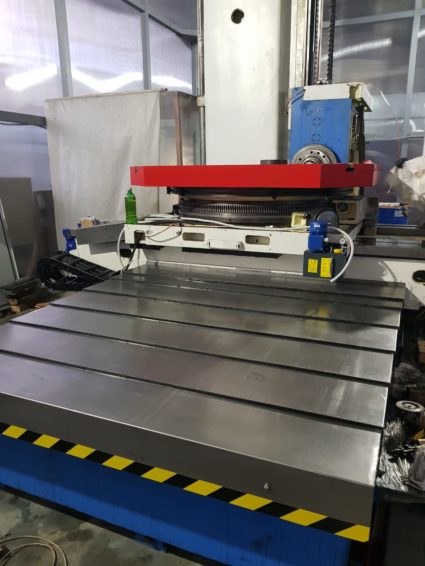

Table rotation is discrete (axis B) from 0 to 360 degrees).

Positioning accuracy of the rotary table + – 5 arc seconds

Retractable spindle with mechanical tool clamping device: 125 mm diameter

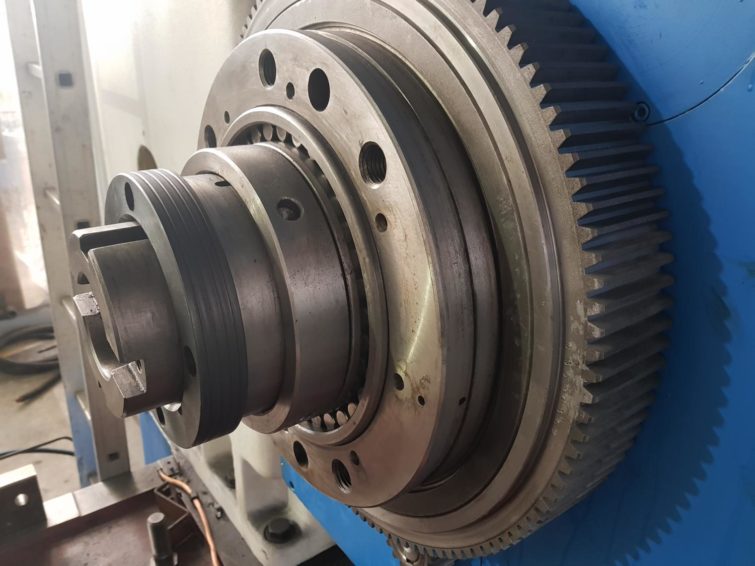

Faceplate (removable) diameter 800 mm, weight 500 kg

The largest diameter of the boring bar inserted into the lune bearing, mm 150

The greatest distance from the center of the table to the face of the faceplate, 725 mm

The shortest distance from the center of the table to the end of the flange of a hollow spindle, mm –

The distance from the spindle nose to the end of the back rest of the stand, mm:

the smallest 1000

most 3450

Spindle speed limits 7.5-1250 rpm

The greatest longitudinal movement of the sliding spindle (Z axis) mm 1000

The greatest vertical movement of the spindle head (Y axis), mm 1400

The speed of the installation movements of the spindle (axis C), the spindle head and the table (lengthwise, transversely and round to f 790 mm),

the smallest 2 mm / min, the greatest 2700 mm / min

The greatest movement of the built-in turntable, mm:

cross, sleigh top (axis X) 1400 mm

longitudinal, sledge lower (axis W) 1600 mm

Limits of the working feeds of the axis X, Y, Z 2.5-2500 mm / min

W axis 2.0-2000 mm / min

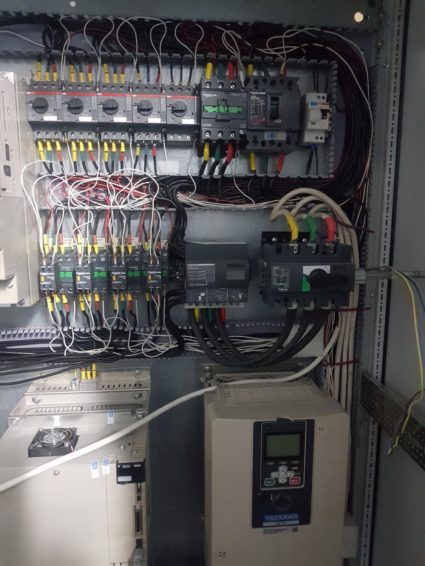

Power Supply: AC, 50 Hz, 380 + -10% Volt

Maximum power consumption not more than 55 kW

The radial movement of the caliper built-in faceplate, mm 200 Spindle speed, rev / min 8-1250

Limits of the speed of rotation of the faceplate, rpm 5-315

The greatest torque on the spindle, kgf * m 350

The greatest torque on the faceplate, kgf * m 550

The greatest cutting force on the spindle, kgf 1600

The greatest cutting force on the faceplate, kgf 1600

The greatest effort of giving of a spindle, kgf 2000

The greatest effort to feed the spindle head, kgf 2000

The greatest longitudinal, transverse and circular (by f 790 mm) force of feeding the table with a mass of a part of 8 tons, kgf 2000

The greatest effort to feed the radial caliper, kgf 700

The limits of the spindle feed, headstock, table (along, across and round on f 790 mm), mm / min 2-1120

The range of feeds of the radial caliper mm / min 2-1120

The speed of the installation movements of the spindle, the headstock and the table (along, across and round on f 790 mm), mm / min:

smallest 2

the greatest is 2,700

Overall dimensions of the machine, mm: length 6830 width 4110 height 4180 Weight of the machine (without electrical equipment and accessories), t 32.0 Mass of the machine with electrical equipment, t 34.6

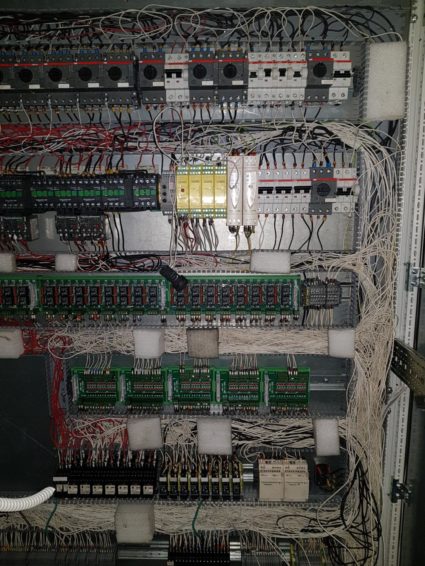

As a result of the upgrade, the following changes were made:

1) The axis X is separated from the axes B and W

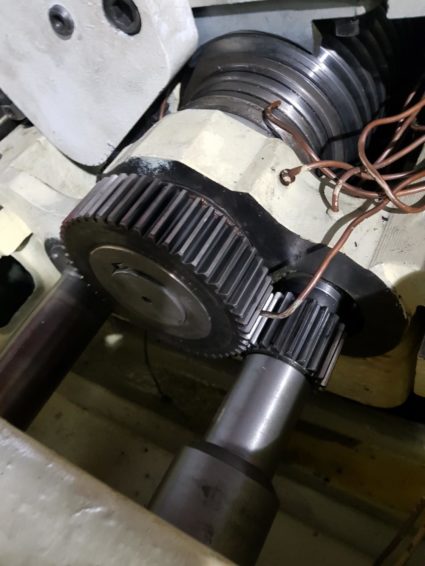

2) The speed of rotation of the spindle and the faceplate is regulated from 0 to nominal by using the GA700 frequency converter and an asynchronous motor of the ADRC series as the main electric drive.

3) The speed box of the spindle and faceplate is modernized and allows operation in 4 ranges M41, M42, M43, M44,

The change of ranges is made both in automatic and in manual modes.

4) Application of linear linear transducers

allows to provide positioning accuracy along linear axes with an accuracy of 0.01 mm, and table rotation with an accuracy of 5 “.

5) The main drive allows you to work in two modes:

a) Classic – the axis of rotation S;

b) axis with linear circular motion C;

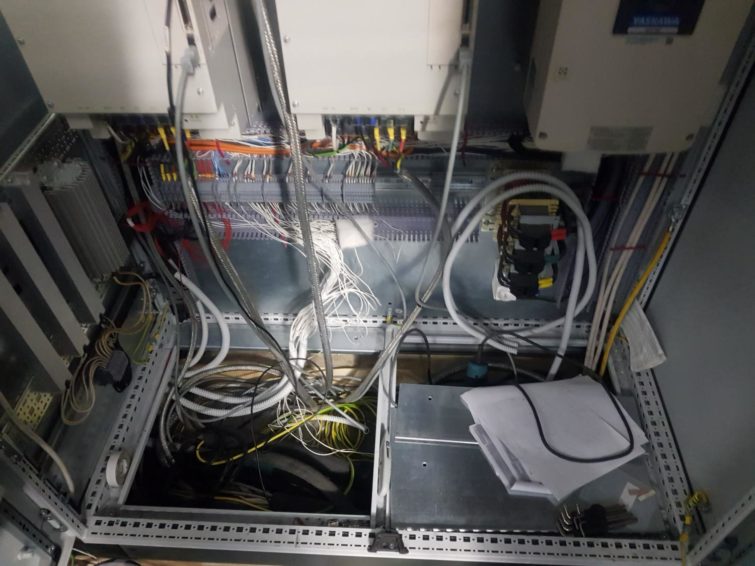

6) CNC ShU – equipped with cooling fan with thermostat

7) SHU EP is equipped with a refrigeration unit.

8) The machine control panel is equipped with electronic indication of the load of the main electric drive and feed drives.

9) The CNC system allows you to display diagnostic, warning and alarm signals.

The radial faceplate caliper provides for the possibility of installing a measuring probe from HEIDENHAIN for the purpose of automated measurement of the geometrical dimensions of the installed product and transferring measurement data to the control program for processing the product. (An additional option. Installation according to your requirement is possible).

10) To comply with ISO-9002 safety standards, the installation of light-sound indication company “RITTAL”

11) Replaced guide lubrication system according to W, X, Y, B, Z coordinates. Instead of lubricators, there are three stations of pulse lubrication produced by “HAOLI”

12) The applied electric feeds and the main electric drive of the company “YASKAWA” can reduce electricity consumption by 30-40%.